We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

The fischer concrete screw UltraCut FBS II SK is a powerful anchoring solution with top installation comfort. The version with the countersunk head enables use for visually demanding anchorings. The European Technical Approval for cracked concrete and non-cracked concrete as well as for seismic loads and classification into fire resistance class R 120 guarantee even more safety. The saw tooth geometry enables a quick and easy installation. No drill hole cleaning is required for installation in ceilings and floors. The expansion-free anchorage system enables low edge and axial spacings.

Advantages

- With up to 3 embedment depths, the UltraCut FBS II US allows for the same screw to be used for different component thicknesses.

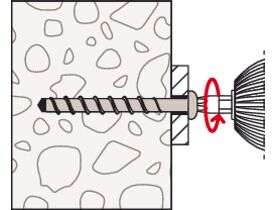

- The special saw tooth geometry enables fast cutting into the concrete.

- Drill holes do not need to be cleaned during vertical installation (ceiling and floor). For floor fixings the hole must be drilled 3x drill hole diameter deeper.

- Expansion-free anchoring (undercut) allows for lowest edge- and axial spacings.

- The ETA approval covers applications in cracked concrete and seismic power categories C1 and C2.

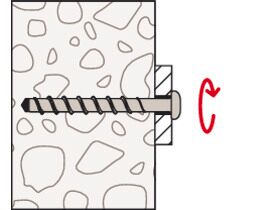

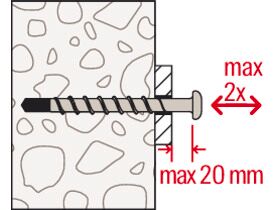

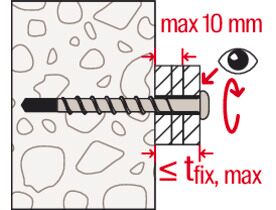

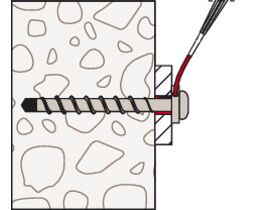

- The approved adjustment for the concrete screws allows the screw to be unscrewed twice to place maximum 10 mm packing below the base plate head or to align the attached part, and then to tighten the screw again.

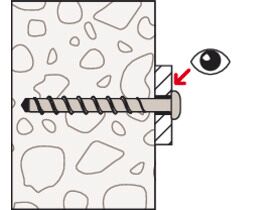

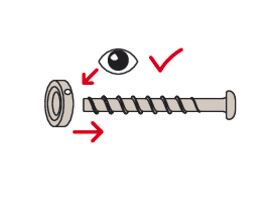

- The checking gauge allows for reuse in temporary fixings (e.g. inclined supports) covered by the national approval.

- The concrete screw FBS II 6-10 in zinc-plated steel, multiple-coated steel CP and stainless steel R has an ETA for bricks of clay (EN771-1), solid sand-lime brick (EN771-2) and perforated sand-lime brick (EN771-2) for a flexible use in different substrates.

- The installation of the concrete screw FBS II 6-10 in zinc-plated steel, multiple-coated steel and stainless steel R in masonry brick can be made in the joints or in plastered substrates also in groups.

Applications

- Guard rails

- Consoles/Base plates

- Metal profiles

- Reinforcement of bridges

- Rehabilitation of old and ailing buildings

- Rehabilitation of car parks

Building materials

Approved for:

- Concrete C20/25 to C50/60, cracked and non-cracked

- Reinforcement of existing concrete structures

- Bricks of clay (EN771-1)

- Solid sand-lime brick (EN771-2)

- Perforated sand-lime brick (EN771-2)

Approval

- ETA-15/0352

- ETA-20/0134

- DoP No. 0185

- DoP No. 0227

- DoP No. 0311

- Z-21.8-2049

Also suitable for:

- Concrete C12/15

- Solid building materials

- Masonry with a dense structure

Specifications

| Diameter | M10 |

| Length | 100mm |

| Material | Carbon Steel |

| Finish | Zinc Plated |

| Hole Diameter | 10 |

| Head Type | Countersunk |

| Drive | TX30 |

| Supplier Part No. | 536887 |

| Max Fixture Thickness (mm) | 45 / 35 / 15 |